I have made silicon pads from caulking for about 3 years for various applications. Sound dampening for the Nickster, bumpers, washers and tubing for the Deagan glockenspiel, stick pads, etc. I've used clear, white, and black, putting in water mixed with dish detergent, mixed it with corn starch, or simply put it between two pieces of paper and pressed until it cured.

Mixing with detergent causes air bubbles in the final product. Corn starch creates a mess. Just pressing works the best.

My normal procedure is to place a sheet of paper on a plywood board, squirt the caulking onto the paper, cover it with a second sheet of paper and put another plywood board on top and press. Remove the top plywood and let it cure. After curing it's placed in a tub of hot water for a day or two and then using a stiff wire brush remove the paper. Brushing is the hardest part. Sometimes I place spacers between the two boards to get an exact thickness of the final pad. I use recycled paper that is printed on one or both sides so as not to waste paper.

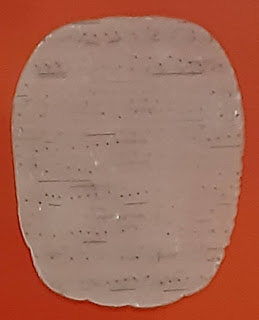

The last batch of pads (for the wood block project) went through this process with one exception: I used paper that was copied not on my inkjet copier but on my laser printer. When I finished the brushing to remove the paper I found that the image from the paper was transferred to the pad.

This is 'The Interesting' in the title. This opens up a lot of possibilities like making practice pads for Christmas presents for my students, personalized with their name and a drum solo on it. Of course the image is reversed but that can be dealt with during the printing process. I'm sure I'll find other uses for it, but for now I'll just file it in my brain.

Interesting...

ReplyDeleteInteresting...I wonder if it would tick to freezer paper or wax paper? Good idea for a gift...you might have a million dollar idea:)

ReplyDeleteI have found that they make good jar openers. I've had to replace the old rubber ones we had.

ReplyDelete